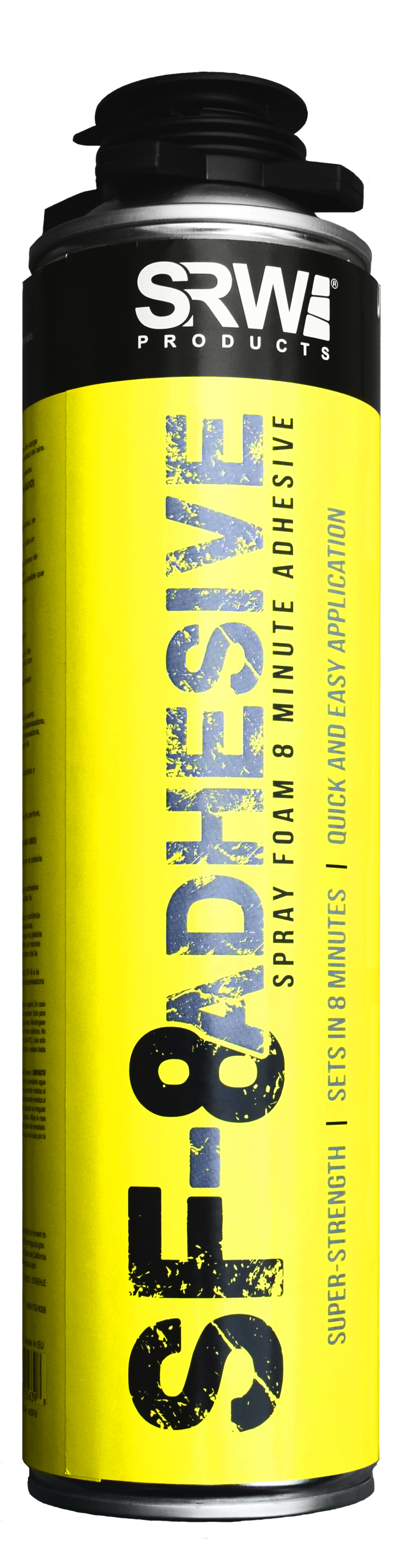

Adhesive

SF-8™

Spray Foam Adhesive

Features

- Fastest set-up time on the market

- Designed for construction and landscape projects

- Suitable for dry or damp surfaces

- High temperature compatible

- Interior/exterior applications

- Premium, long-lasting strength

- 12 month shelf life

- Coverage: 3/8” bead for 600 linear ft

Applications

- Retaining Block

- Pavers

- Concrete

- Natural Stone

- Brick

- Porcelain

- Steel / Metals

- Aluminum

- PVC

- Vinyl

- Wood / Plywood

- Composite Materials

- Drywall

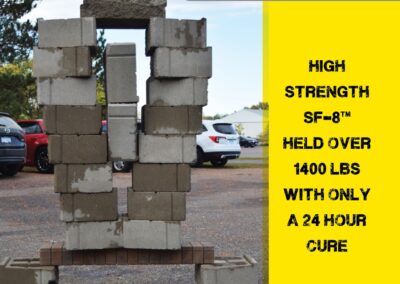

SF-8™ Spray Foam Adhesive is a strong and durable 8-minute tack-free polyurethane adhesive. This adhesive is easy to use with a wide range of construction and hardscape materials, works fast, and provides optimal coverage. Highly recommended for use with retaining wall blocks and caps. Materials are fully cured within 24 hours. Application time is up to 50% faster than conventional tube adhesives. One can of SF-8™ will replace 20+ traditional tubes of adhesive. One can of SF-8™ can produce a 3/8” bead for 600 linear feet, or approximately the length of two football fields. When using with the SF-8™ dispenser gun you can expect an easy and precise application. This adhesive requires no pumping, cutting or puncturing of cartridge nozzles. The SF-8™ Dispenser is easily cleaned with convenient SF-8™ Cleaner.

Instructions

PREPARATION

- Before using, make sure you have an up-to-date technical data sheet available at SRWProducts.com.

- TEST IN A SMALL DISCRETE AREA to ensure compatibility before use. For industrial use only. Always wear gloves and safety glasses when using this product.

- Protect floor (if applicable)

- Remove all particles of dust and grease from the surface to be bonded. A faster cure can be obtained by misting the adhesive after it has been applied to one side (Complete curing will take approximately 24 hours)

- Shake canister vigorously at least 20 times before each use

- Check forecast (if applicable) to ensure temperatures will be 32- 95°F (0 – 35°C)

- Necessary tools (sold separately):

APPLICATION

- Remove the protective cap and screw adhesive tube onto the dispenser gun.

- Before putting the first can on a new gun, open the valve slightly and pull the trigger. A small amount of air may be trapped. For best results, always work with the canister in a vertical position and keep the valve pointed downwards.

- Once the canister of SF-8™ is screwed to the gun, make sure to extrude enough adhesive to fill the gun and nozzle. Never allow the gun to run empty of adhesive.

- Apply a 3/8” bead of adhesive along the horizontal and vertical sections of the material to be bonded. If different size bead is needed, the bead size can be adjusted by turning the adjustment dial on the gun.

-

Wait a few seconds for adhesive to fully expand on the surface then bond both pieces together by pressing slightly. No need to twist.

-

Remove excess adhesive immediately. Remove any adhesive at the tip of the gun. Dried adhesive at the tip could make the gun shoot sideways instead of straight. See cleaning step for details.